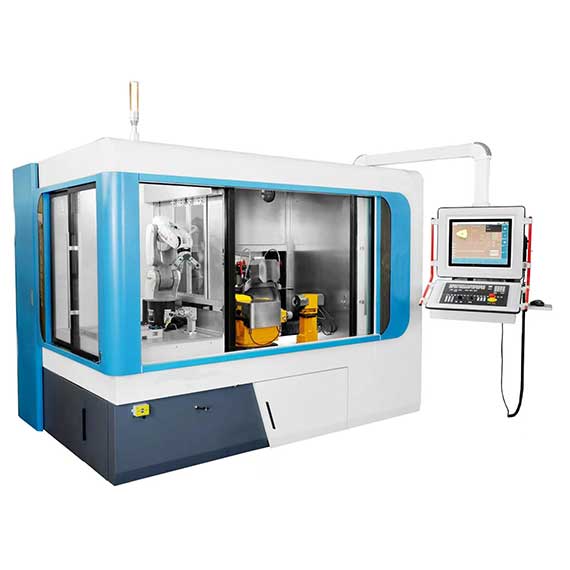

·Excellent performance of CNC Indexable Inserts Grinding Center

Independent research and development, the first four-axis full direct drive technology in China, with the world's leading, the application of four-axis full direct drive technology, make the machine achieves higher accuracy and better accuracy retention.

·Powerful function of CNC Indexable Inserts Grinding Center

With graphical interaction and custom programming, the Industry 4.0 suite can connect devices directly to the Internet of Things, once the clamping can complete the grinding of the periphery and bilateral chamfering of the blade, and the extended cylindrical grinding function of the wheel can be used for the concave surface of the special blade Circular grinding.

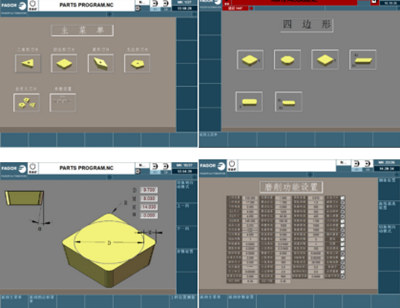

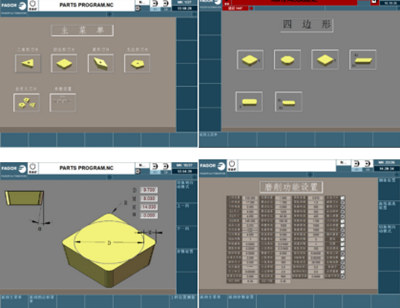

·Graphic interactive programming

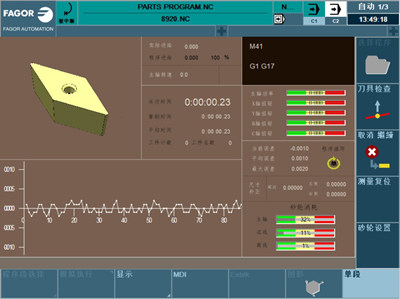

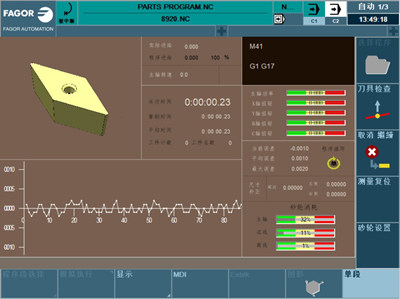

·Professional grinding interface of CNC Indexable Inserts Grinding Center:

·Professional grinding interface of CNC Indexable Inserts Grinding Center:

After secondary development of the blade grinding user interface, simple and intuitive display of the user needs a variety of data, comfortable, sensitive touch screen and interface navigation function, can more easily access different operating modes, minimize the operation steps.

·Overview of each axis of CNC Indexable Inserts Grinding Center:

·Overview of each axis of CNC Indexable Inserts Grinding Center:

X-axis grinding wheel longitudinal feed shaft linear motor equipped with absolute value grating rule full closed-loop control

Y-axis grinding wheel transverse feed axis linear motor equipped with absolute value grating rule full closed-loop control

B-axis workpiece spindle rotary motion direct drive motor equipped with absolute encoder full closed-loop control

C-axis table rotary motion direct drive motor equipped with absolute encoder full closed-loop control

U-axis online cleaning shaft servo control

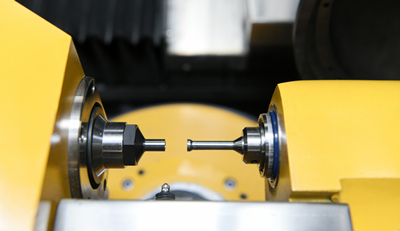

·Advanced direct drive technology of CNC Indexable Inserts Grinding Center

The feed shaft involved in grinding adopts advanced direct drive technology, which reduces the mechanical transmission error and mechanical wear, and improves the accuracy retention. The high-torque direct drive motor is combined with the absolute closed-loop feedback to ensure the fast response and high-speed operation of each shaft, and achieve high precision and high efficiency machining.

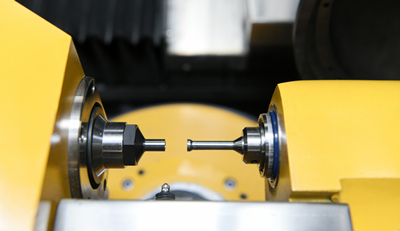

·Permanent magnet synchronous motorized spindle in CNC Indexable Inserts Grinding Center

The grinding wheel spindle adopts permanent magnet synchronous electric spindle technology, and its unique constant torque control ensures that the spindle motor can obtain a constant torque no matter what speed it works at, ensuring the optimal rigidity, shock resistance and durability of the spindle mechanism.

·Measuring System in CNC Indexable Inserts Grinding Center

The inserts size measurement system can realize automatic alignment, calibration position, measurement and compensation size, can check the blade after processing, and cooperate with the manipulator to separate unqualified products. The blade thickness measurement system can ensure the machining accuracy of double-sided negative chamfering

·Industry 4.0

·Remote diagnosis

·Simulation software

·Fast, highly flexible manipulator unit

1. The highly flexible six-degree of freedom manipulator makes the blade loading and unloading more flexible and efficient, and can optimize the movement mode by itself.

2. The clamps of the manipulator can be held by magnet, vacuum or hole

3. Optional tray storage function, can be put into 15 horizontal tray, the refuelling tray independent operation, does not affect the machine processing.

4. The manipulator platform can be placed with two plates. The optimized six-degree-of-freedom manipulator can load and discharge materials from the plate at the same time during the grinding process, without occupying the grinding time, thus improving the production efficiency.

5. Disk storage area and blade processing area are separated by automatic doors to prevent oil mist from entering the blade storage area.

·Grinding wheel

400mm large grinding wheel makes the grinding process more stable, depending on the need to grind the product, you can choose different shapes of grinding wheel flanges.

·

Grinding wheel dressing in CNC Indexable Inserts Grinding Center

The combination of the newly designed online cleaning and external dressing ensures the flatness and sharpness of the grinding wheel, and the efficiency of grinding ceramics, CBN, PCD and other superhard materials is higher.

·

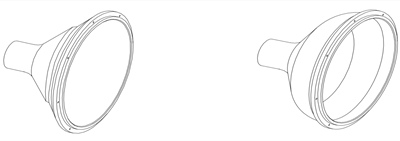

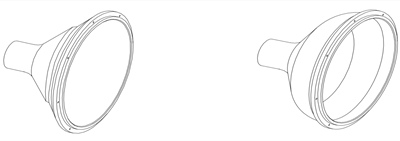

Typical work piece processed by CNC Indexable Inserts Grinding Center

.jpg)